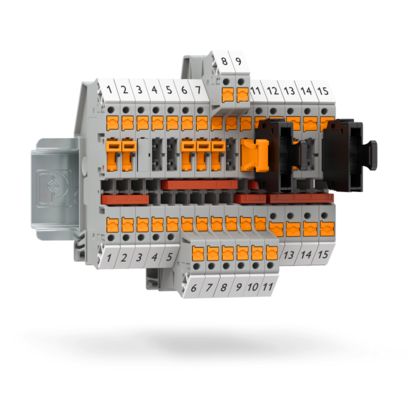

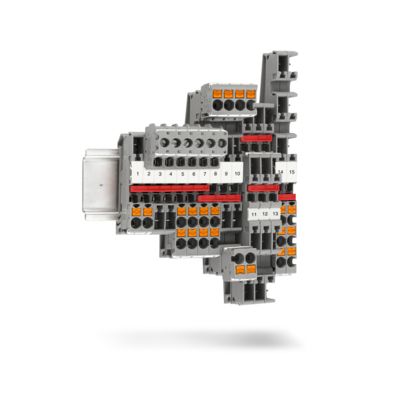

Terminal blocks with system

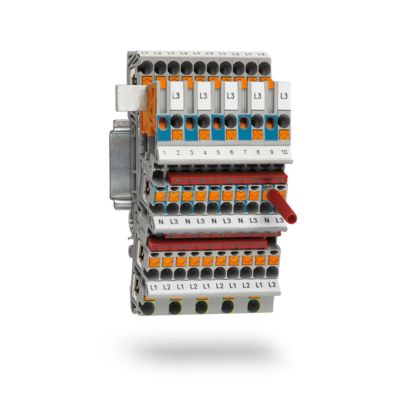

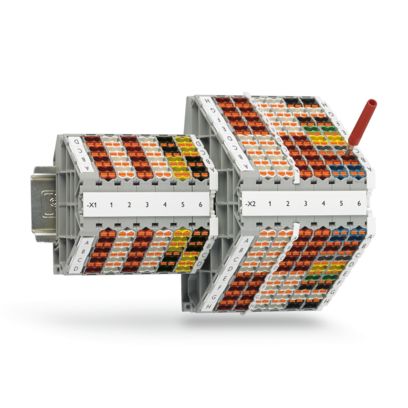

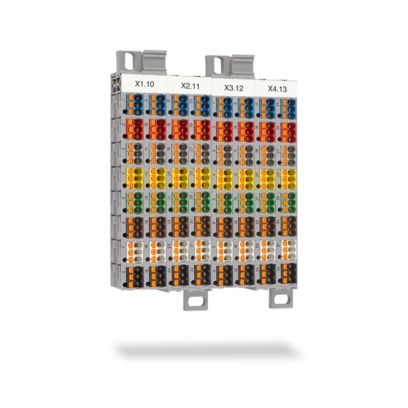

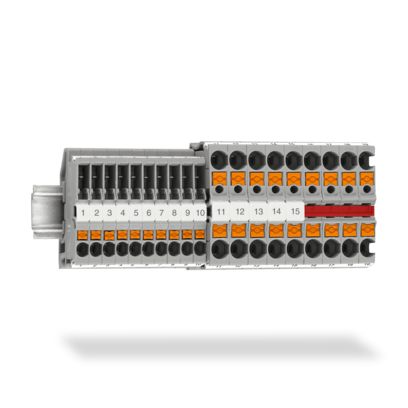

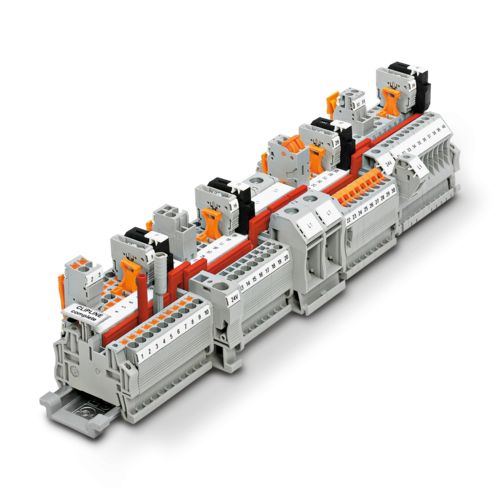

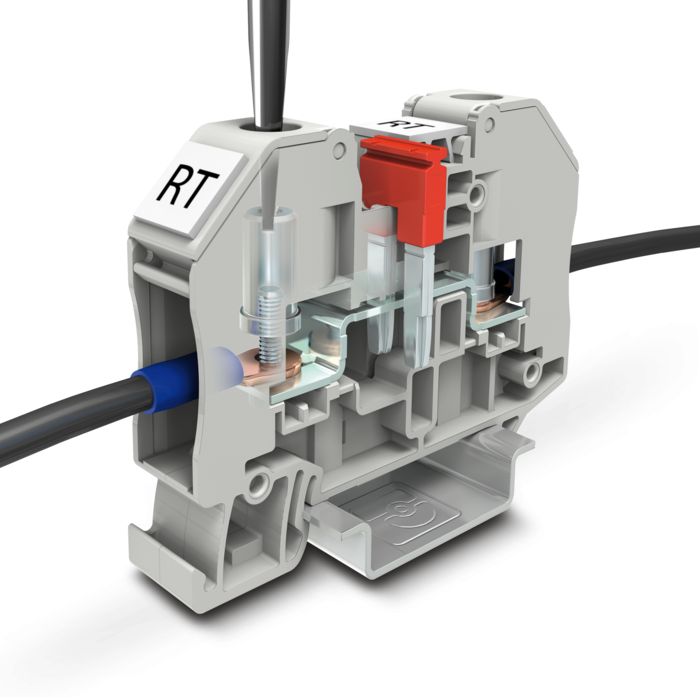

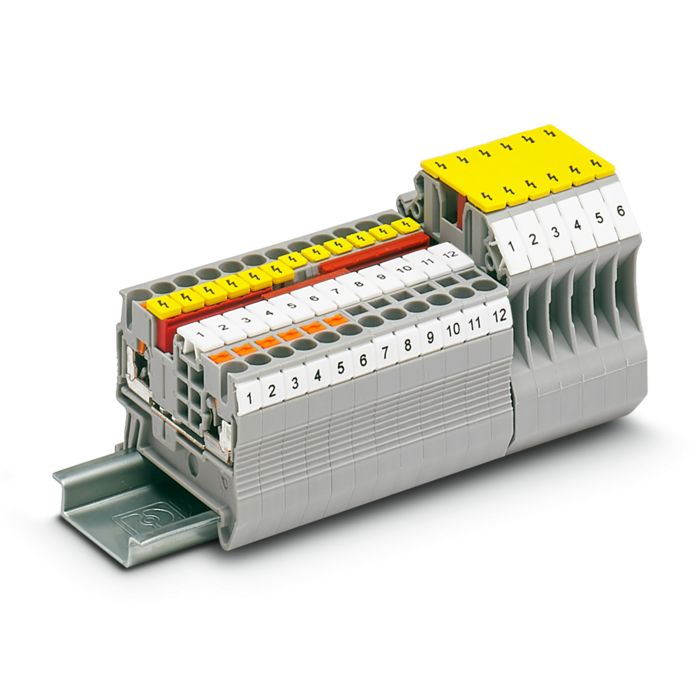

The Phoenix Contact terminal blocks enable a high degree of flexibility in terminal strip design. Choose between various connection technologies and combine the terminal blocks by installing bridges in the double function shaft. The terminal block system features standardized bridging, marking, and test accessories.

More informationYour advantages

- Complete flexibility: Terminal blocks with different connection technologies can be freely combined

- Bridging and testing option with double function shaft

- Additional test option with integrated test points, eliminating the need for removing conductors or bridges

- Save money with uniform bridging, marking, and test accessories

- Extensive digital data

New products

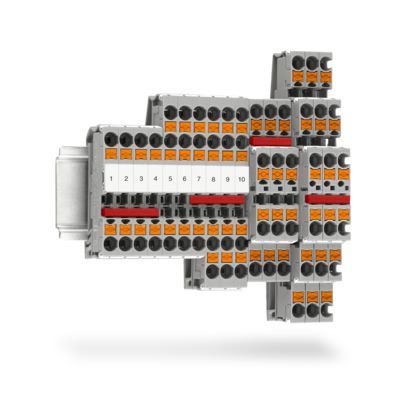

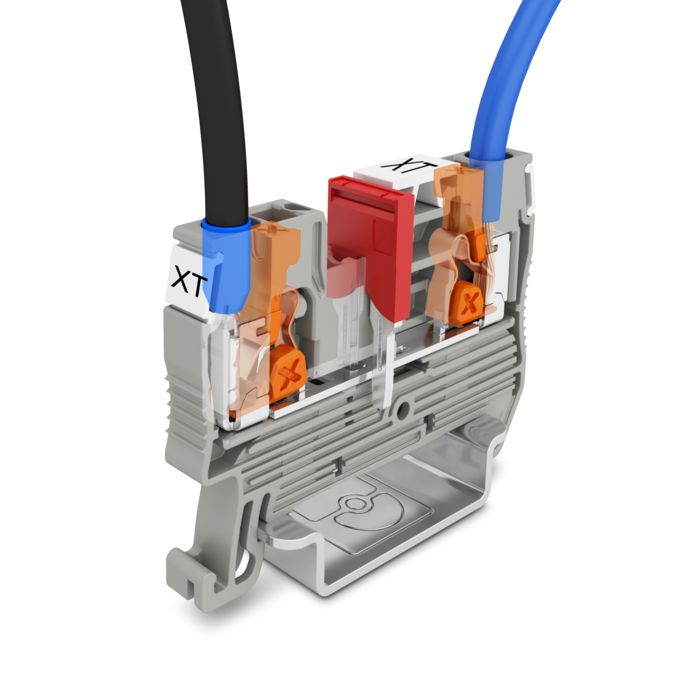

Terminal blocks with Push-X technology

For effortless and fast wiring

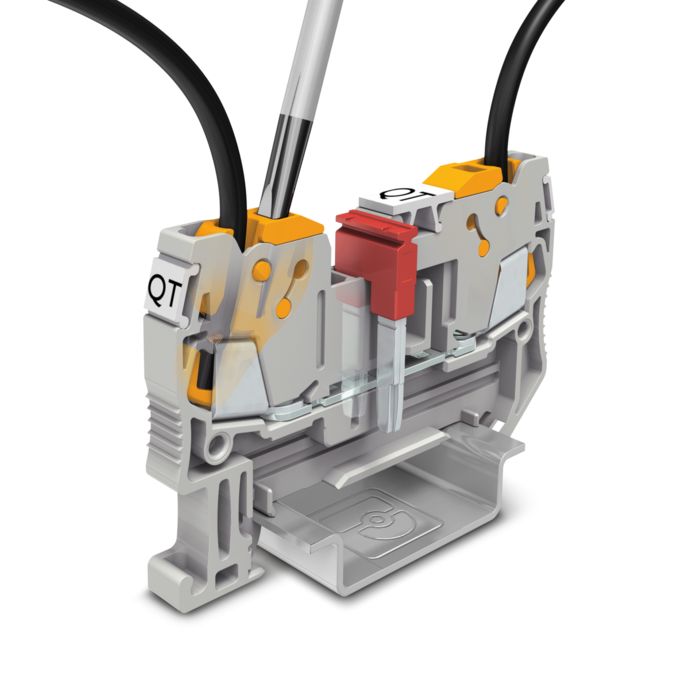

The new XT terminal block family enables you to wire conductor cross-sections of 0.5 to 4 mm² within a few seconds and without any significant effort. The front-end Push-X technology enables tool-free wiring of rigid and flexible conductors with and without ferrules.

Main features

- Push-X technology

- Nominal cross-section: 2.5 mm²

- 20 AWG … 12 AWG

- Nominal current: 24 A

- Nominal voltage: 800 V

Your Advantages

- Feather-light plugging and superior handling comfort with a pretensioned contact spring

- Reduced installation times with the factory-opened clamping space

- Clear identification of the conductor connection with the force-guided actuating element and the acoustic click sound when the spring is released

- Wiring of all conductor types, whether rigid or flexible with and without ferrules

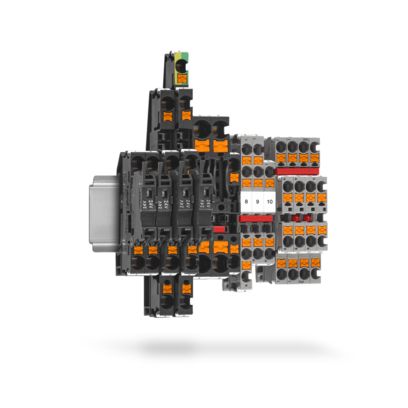

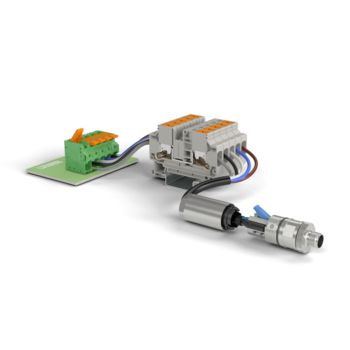

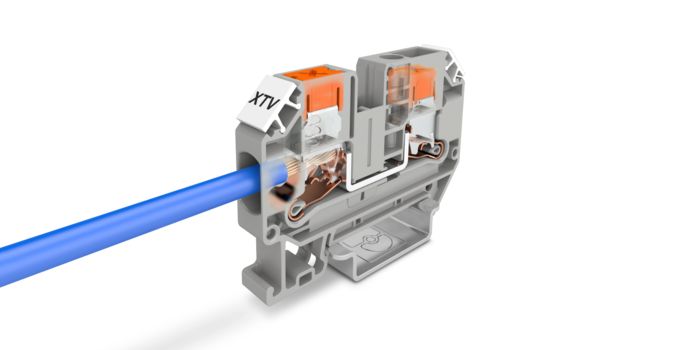

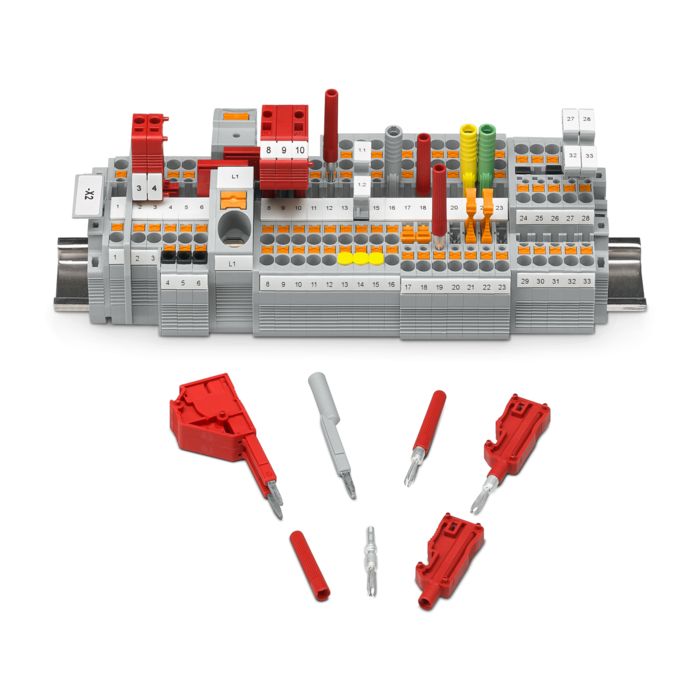

LPS service connectors

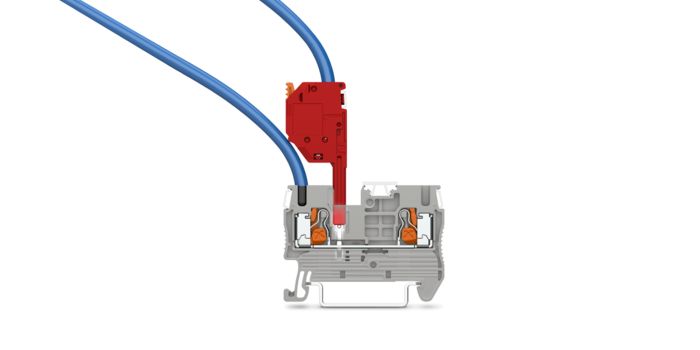

For quick and easy testing

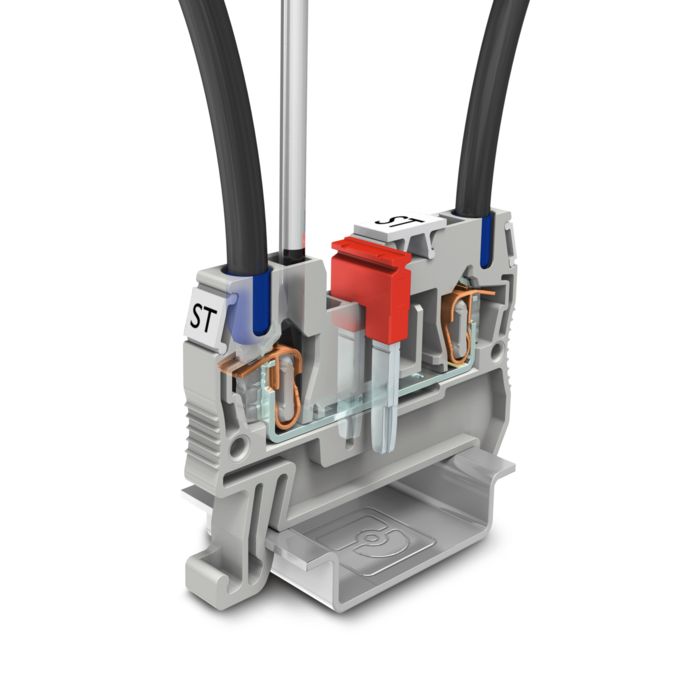

The LPS service connectors are suitable for various testing applications. The connectors are equipped with lever Push-in technology, which enables quick wiring and rewiring. The contact springs have a silver-plated surface to ensure permanent and consistent quality.

Main features

- Lever Push-in technology (LP)

- Silver-plated surface of the current-carrying parts

- Nominal current: 24 A

- Nominal voltage: 800 V

- Modular versions

Your Advantages

- Maximum ease of operation – the lever technology enables fast and effort-saving wiring

- High-level flexibility – connection of different conductor types with and without ferrules

- Quick mounting – simple integration into the function shaft of the terminal blocks

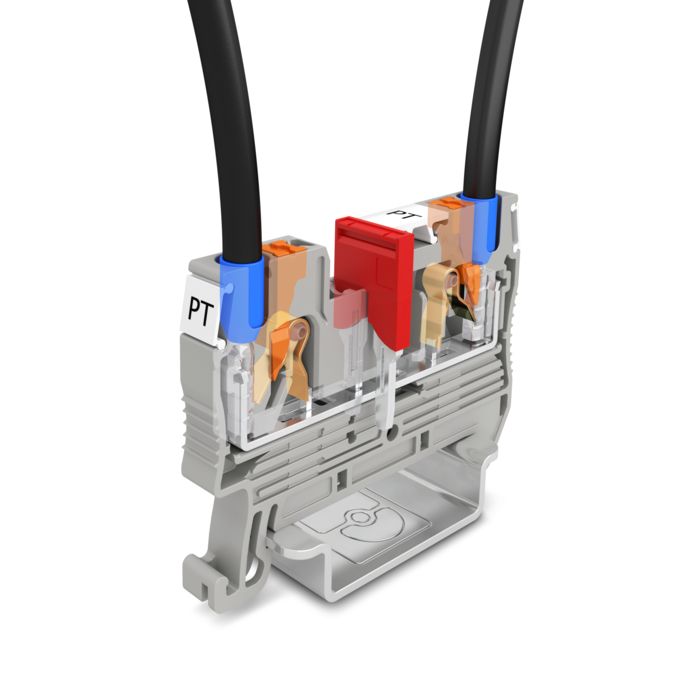

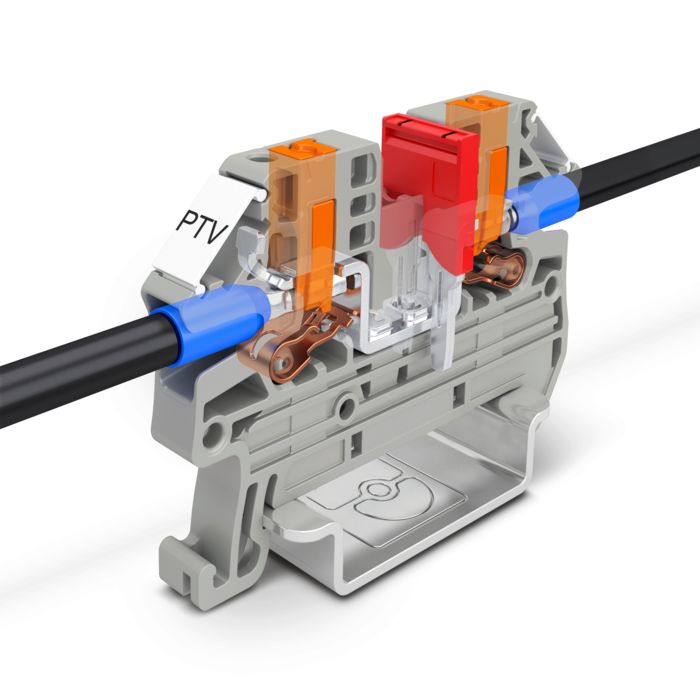

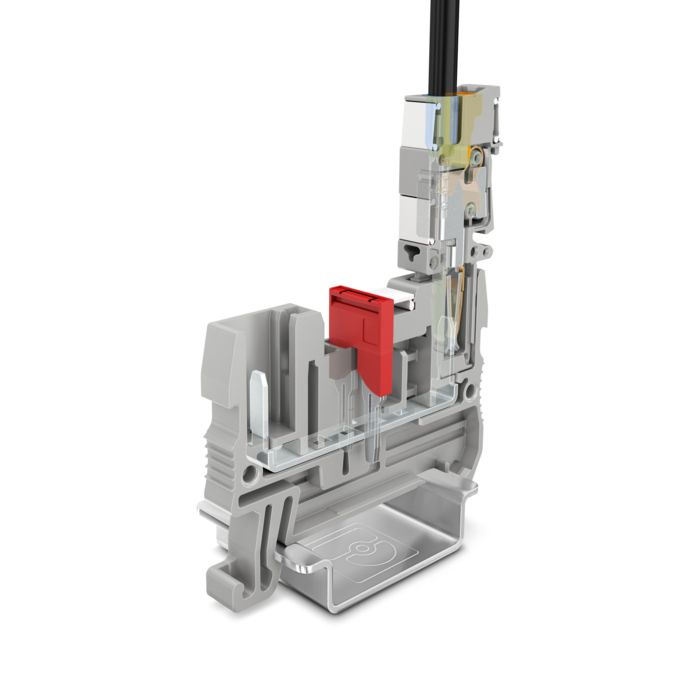

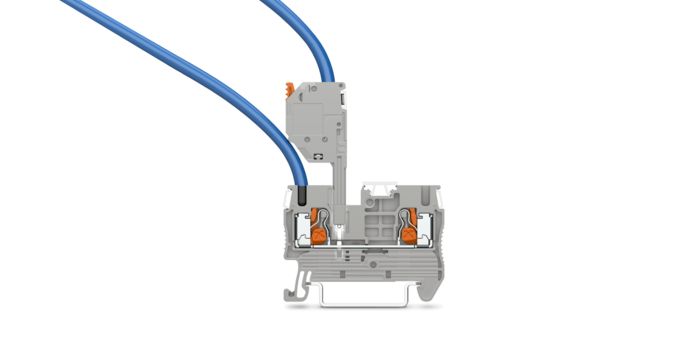

LPO pick-off plugs

Additional load pick-offs quickly integrated

The LPO pick-off plugs with lever Push-in technology enable the simple integration of additional load pick-offs via the function shaft of the terminal blocks. This means the LPO plugs provide a significant advantage, especially if design changes are necessary in the control cabinet.

Main features

- Lever Push-in technology (LP)

- Special spring design for high holding forces

- Nominal current: 24 A

- Nominal voltage: 800 V

- Modular versions

Your Advantages

- Maximum operating convenience – the lever technology enables quick and easy wiring

- High-level flexibility – connection of different conductor types with and without ferrules

- Quick mounting – simple integration into the function shaft of the terminal block

- Secure connection – the design of the pick-off plugs enables a durable and robust connection

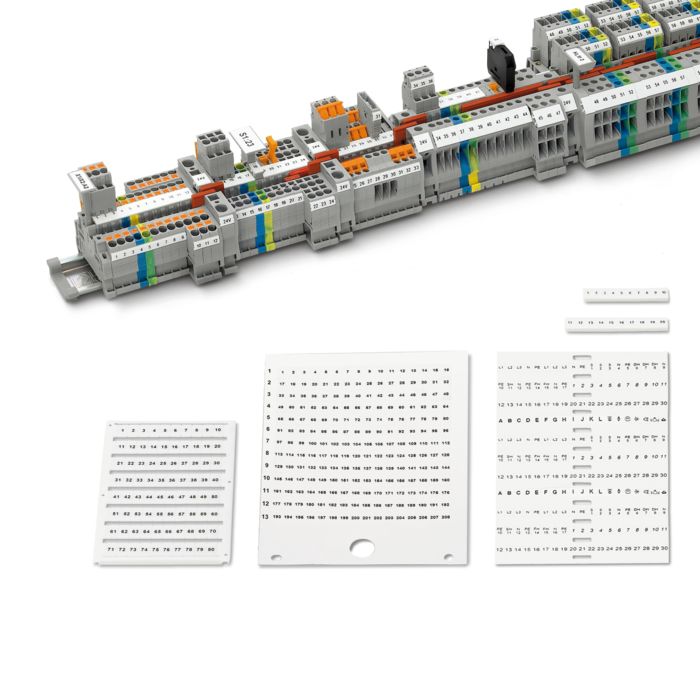

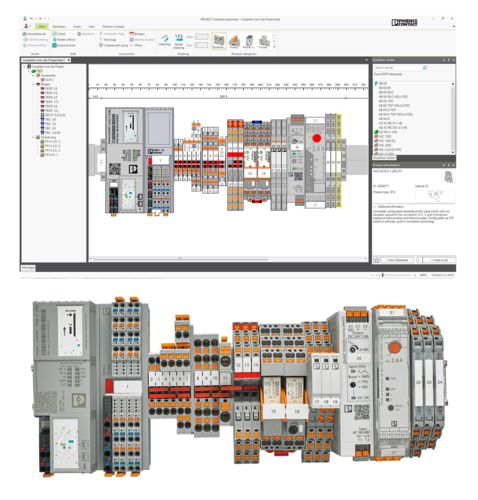

PROJECT complete configuration software

The system provides the opportunity to freely and flexibly combine the different terminal blocks using the double function shaft.

The system has uniform bridge, marking, and test accessories. You can lower your logistics and storage costs through the resulting reduction in individual parts.

Create terminal strips quickly and effectively using our free PROJECT complete configuration software.

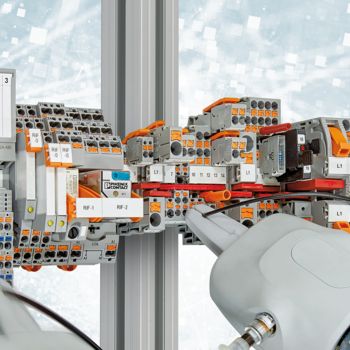

CLIPLINE complete terminal block system

Terminal blocks exceed the requirements imposed by standards

The terminal blocks from Phoenix Contact have been tested and approved for a wide range of national and international approvals. The terminal blocks are very resistant to environmental influences, which is why they are designed for pollution degree 3. This degree indicates that conductive contamination in the form of dust, liquids, or gaseous substances can occur. In addition, the terminal block materials provide you with long-term stability and guarantee long-term reliability. The terminal blocks exceed the requirements imposed by standards in various industries with their material properties and their electrical and mechanical properties. The terminal blocks are tested throughout the entire manufacturing process to ensure that this level of quality is consistently maintained.

Connection technologiesfor the CLIPLINE complete system

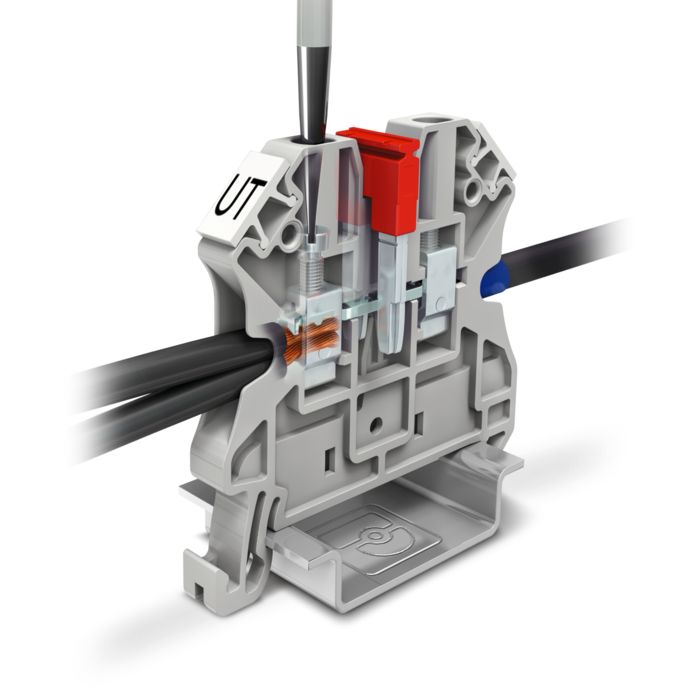

XT terminal blocks with Push-X technology enable easy connection of rigid and flexible conductors with or without ferrules. Even the smallest and most flexible conductors can be clamped quickly and easily with the pretensioned contact chamber. Simply insert the conductor to the end of the chamber. Pressing down the locking mechanism at the end of the chamber releases the contact spring and snaps it shut rapidly. The XT terminal blocks are initially available with a nominal cross-section of 2.5 mm².

The terminal blocks with screw connection technology have been known and accepted worldwide for over 80 years. The screw connection provides maximum contact force and is maintenance-free thanks to the Reakdyn principle. The terminal blocks allow multi-conductor connection at just one terminal point. Connect copper conductors with up to 240 mm² cross-section without any pretreatment.

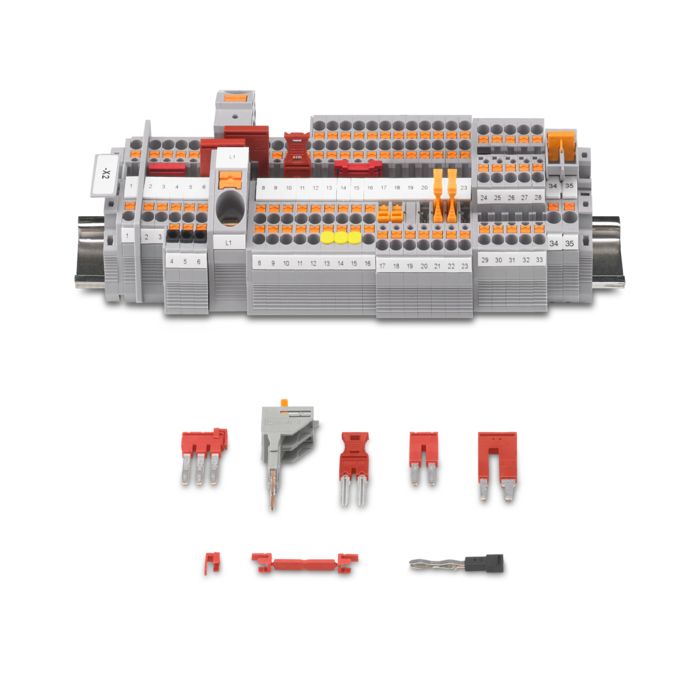

Accessoriesof the CLIPLINE complete terminal block system

The standardized bridge accessories of the CLIPLINE complete system enable simple potential distribution, bridging between non-adjacent terminal blocks, and reducing bridging of the terminal blocks.

This allows you to carry out all bridging tasks quickly and flexibly.

Phoenix Contact offers the following bridge versions:

- FBS standard plug-in bridges

- RB reducing bridges

- Bridge bars

- PV potential bridges

The LPS service connectors are suitable for a variety of testing applications. The LPS connectors are equipped with LP technology (Lever Push-in technology), making repeat wiring quick and easy. In addition, the lever connection enables easy one-handed operation, resulting in high wiring convenience. The contact springs have a silver-plated surface to ensure that the connectors provide consistent and long-lasting quality. In addition, the connectors are designed so that they can be inserted into the multifunction slot over and over again without requiring a great deal of force.

Planning and marking software

Efficient planning with PROJECT complete

Efficient planning with PROJECT complete

Intuitive configuration, intelligent functions, and a customizable user interface: The PROJECT complete planning and marking software is the innovative solution for the easy planning of your terminal strips and the straightforward creation of the corresponding markings.

From the transfer of data from electrical planning to delivery of your finished product, the software features individual and convenient process support.

Product brochure on the subject of terminal blocks

Downloads

Brochures about terminal blocks

Would you like to get printed information about our terminal blocks? Below you will find various brochures on the subject of terminal blocks and marshalling panels. In addition to the product brochures, you will find a brochure about the CLIPLINE complete terminal block system and about the quality tests for the terminal blocks.